Amish woodworking is built on generations of tradition, where timeless techniques and hand tools replace modern machinery. Craftsmen rely on skills like precise joinery, hand-finishing, and careful hardwood selection to create furniture that is strong, functional, and elegant. These methods go beyond practicality; they reflect a philosophy of patience, sustainability, and pride in craftsmanship, making Amish furniture renowned for its durability and timeless appeal.

Key Takeaways:

- Amish woodworking techniques emphasize solid wood construction, structural joinery, and movement-smart details.

- Traditional Amish woodworking tools include hand planes and chisels, hand saws, brace-and-bit drilling, and shaping with a drawknife and spokeshave.

- Core skills cover grain matching, proper seasoning and drying, steam bending, and meticulous hand-planed surface prep.

In this article, we’ll explore the artistry of Amish woodworking, from the traditional tools and time-honored techniques to the skills that have been passed down through generations.

What Amish Woodworking Is and Why It’s Special

Amish woodworking is the traditional craft of making durable, heirloom-quality furniture and wood products using solid hardwood, classic joinery techniques, and a mix of hand tools and air-powered tools. Its reputation hints at something deeper than craftsmanship alone, inviting a closer look at what it is and why it holds such a special place in furniture-making.

Emphasis on Handmade Craftsmanship

Amish woodworking relies on precise handwork to create smooth, lasting finishes. Craftsmen plane, scrape, and chisel joints so parts meet seamlessly without gaps. The result is a surface that feels even to the touch and is ready for finishing.

Use of Solid, Quality Wood

Durable, solid hardwoods like oak, maple, cherry, and walnut are chosen for their strength and repairability. Unlike veneers or particleboard, solid raw wood can be refinished, steamed, or sanded to restore its beauty.

Focus On Timeless, Simple Designs

Amish designs emphasize clean lines and proportions that age gracefully. Features like floating panels and breadboard ends prevent cracking and warping over time. Hardware is functional and understated, supporting longevity rather than trendiness.

Blend of Traditional Skills With Some Practical Adaptations

While handcraft remains central, Amish shops incorporate select tools for safety and efficiency. Dust collection, pneumatic sanders, and shaping jigs aid in consistency without replacing skill. The most critical joints, surfaces, and details are still refined entirely by hand.

Traditional Tools Used by Amish Woodworkers

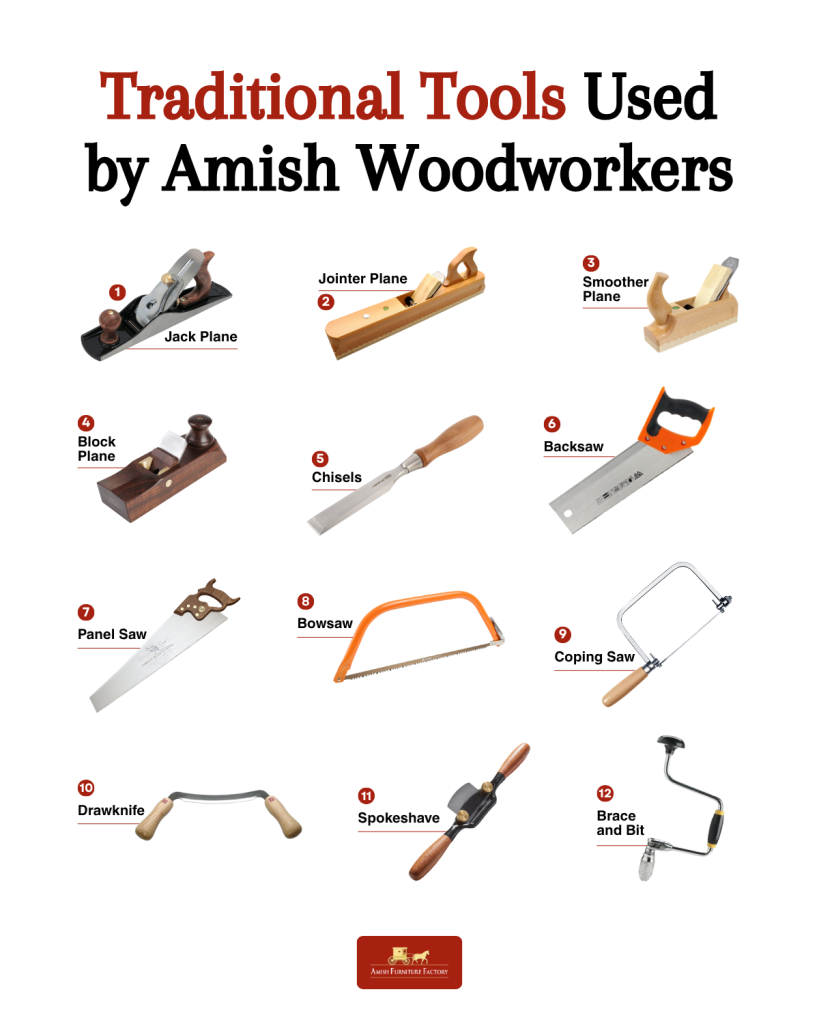

A solid woodworking toolkit relies on a handful of versatile hand tools that deliver accuracy and control. Each one has a distinct role in shaping, smoothing, and fitting wood with precision.

- Hand planes – A jack plane flattens rough boards, a jointer plane trues edges for gluing, and a smoother leaves the final pass for a glowing surface.

- Block planes – Ease sharp corners so they resist chipping and feel comfortable to the touch.

- Chisels – Cut mortises, pare to a scribed line, and refine shoulders for tight joints.

- Saws – Backsaws handle dovetails and shoulders with accuracy, while panel saws break down stock with straight, square cuts.

- Curved-cutting tools – A bowsaw or coping saw removes waste, while a drawknife and spokeshave refine curves with clean, controlled cuts.

A solid workbench and careful layout also play a key role. Secure grips prevent bruised edges so parts meet cleanly. Knife-marked lines guide saws and chisels for crisp shoulders, and precise measuring keeps doors straight and drawers running smoothly. When drilling with a brace and bit, holes come out clean and centered, all adding up to joints that stay tight and pieces that feel stable through years of use.

Common Amish Joinery Methods

When it comes to building furniture that lasts for generations, the Amish rely on time-honored joinery techniques passed down through centuries. These methods not only ensure strength and durability but also reflect the craftsmanship and care that define Amish woodworking.

Mortise and Tenon Construction

Mortise and tenon joints form the core of Amish tables, chairs, and frames. The tenon fits snugly into the mortise, creating a strong connection that holds up under heavy use, especially when reinforced with drawboring—a technique where peg holes are offset so the peg pulls the joint tight before the glue sets.

Hand-Cut Dovetails and Drawer Building

You’ll often see hand-cut dovetails in Amish drawers and cases because they’re super strong, especially when pulled. The angled shape locks the joint tight, making it nearly impossible to pull apart. For a cleaner look, half-blind dovetails hide the joints at the front, while through dovetails at the back add extra strength. The solid wood drawer bottoms sit in grooves that allow for some movement with humidity, preventing cracking or warping. The best have the grain running side to side with a little extra space at the back to expand easily.

Pegged Joints and Breadboard Ends

Pegs aren’t just decorative—they actually lock joints securely in place. Often found on legs or rails, they’re a sign of quality craftsmanship, especially when used with drawboring, where the peg fits into an offset hole to pull the joint tight.

Breadboard ends are another clever feature, especially on tabletops, helping wide wood surfaces stay flat while allowing natural expansion and contraction. Usually, the center is pinned to keep everything aligned, while the outer ends float in slightly elongated holes. If you see small gaps near the edges during dry months, that’s normal and shows the piece is built to last.

Bring true Amish craft to your workflow with the Bordeaux Amish Adjustable Desk. Hand-planed hardwood and classic joinery deliver heirloom strength with smooth sit-stand control.

How Amish Woodworkers Pick and Prepare Their Wood

When you buy Amish furniture, you’re not just getting solid wood—you’re getting solid craftsmanship. From selecting the right boards to finishing each surface by hand, every step is done with purpose and precision.

Choosing the Right Hardwood

Great furniture starts with the right wood, and Amish craftsmen choose each board with purpose. They hand-select hardwoods based on strength, wood grain patterns, and color—white oak for durability, maple for its hardness and smooth finish, cherry for its rich aging tone, and walnut for deep, warm grain. Each species is matched to the piece it suits best, with care taken to align grain direction and color across parts for visual balance and structural integrity.

Designing for Wood Movement

To keep furniture stable through seasonal changes, wood is dried carefully, then joined in ways that allow it to move without cracking. You’ll often see frame-and-panel doors that flex with humidity, breadboard ends that keep tabletops flat, and floating drawer bottoms that shift without splitting. These subtle construction details protect the piece for decades of daily use.

Finishing by Hand

The Amish furniture finishing process is just as deliberate. Amish makers often hand-plane or scrape surfaces to preserve the grain, then apply stains, dyes, or natural oils based on the wood type. A topcoat—whether a durable varnish or a repairable hardwax oil—protects the surface while highlighting the wood’s natural beauty. Always ask your maker about the finish and how to care for it long-term.

Learn how the ergonomic design and stunning finish of oak standing desk can instantly elevate your health and productivity.

Conclusion

Amish woodworking stands apart because it is rooted in more than just tradition. It reflects a way of working that values patience, precision, and pride in every step. From carefully selecting solid hardwoods to hand-cutting joinery and applying a thoughtful finish, each piece is made with care and meant to last for generations.

These are not just furniture pieces. They are heirlooms built with purpose, designed to be used and appreciated every day. When you understand the tools, techniques, and choices behind the craft, you gain a deeper respect for the skill involved and the timeless quality that defines Amish furniture.

Frequently Asked Questions

How do Amish power woodworking tools?

The Amish use power tools carefully and selectively, mostly for rough cutting and efficiency, while relying on hand tools for precise work. They balance tradition with practicality, using power tools without compromising craftsmanship.

Do Amish use screws?

Yes, the Amish do use screws, but mainly in hidden or structural areas where extra strength is needed. They prioritize traditional joinery like mortise and tenon, but aren’t opposed to screws when appropriate.

What type of furniture do the Amish make?

The Amish make durable, timeless furniture like tables, chairs, dressers, and cabinets, focusing on solid hardwood and classic, simple designs. Their pieces are built to last for generations with strong joinery and quality finishes.

How do the Amish stack wood?

Amish woodworkers stack wood carefully with spacers between boards to allow air circulation for proper drying and seasoning. This method helps prevent warping and ensures the wood remains stable for furniture making.