Wood furniture fills stores, but many people struggle to tell whether makers built it with care. Sellers label a tabletop “handcrafted,” yet the finish looks plastic, the construction feels light, and screws replace joints. Prices rise and trust falls. Most people no longer recognize authentic craftsmanship, so imitation passes as the real thing. Old Order Amish shops fix that gap with quiet, deliberate work in non-electric spaces. The tools and habits are simple and consistent. They create surfaces and joints that hold up over time.

Key Takeaways:

- Most people can’t spot authentic handwork, so imitations sell easily.

- Amish shops use traditional hand tool woodworking in quiet, non-electric settings.

- Simple, disciplined methods yield durable surfaces and strong joints.

- This guide shows which tools and joints leave readable cues in photos and listings.

To see why this approach lasts, start with the story of the tools and the practices that shaped them.

History of Amish Woodworking Tools

Old Order Amish craftsmanship developed alongside American industry but kept a slower pace. Many communities chose continuity to preserve attention in the shop, retain local skill, and keep repairs within reach of family and district. Traditional hand tool woodworking fits that aim because tools serve for decades, pass through hands, and reward practice rather than frequent replacement.

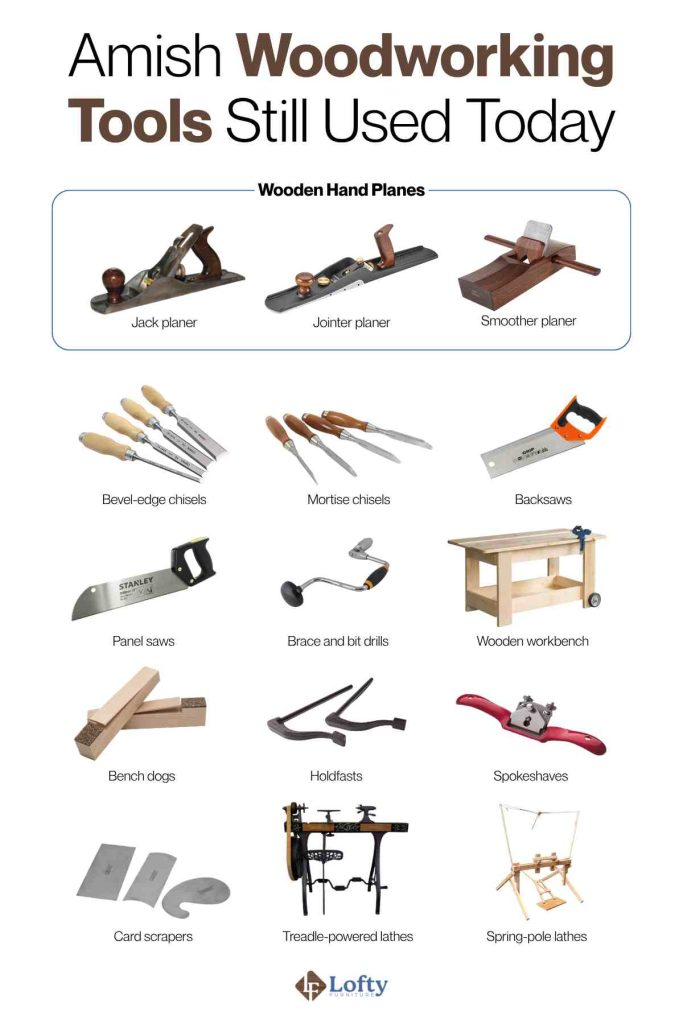

Typical early kits included planes such as jack, jointer, and smoother, bevel-edge chisels for paring, mortise chisels for levering and chopping, backsaws and panel saws sharpened with a file, and a brace with bit augers for controlled holes. Power entered some shops within clear limits. A central air compressor in a separate building could drive modest air tools without wiring the bench. In some districts, line shafts or hydraulic drives handled rough milling while handwork set the final fit and surface.

Tools as Cultural Symbols

In this setting, tools express values and do the work. A well-tuned hand plane needs a sharp iron, a tight mouth, and a controlled cut. A sharp brace bit starts and exits cleanly, so tear-out drops and layout stays intact. Bevel-edge chisels handle paring, while mortise chisels handle levering and chopping. Used this way, the kit builds timing and control through steady feedback.

Planed and shaped surfaces leave visible, readable marks. Spokeshaves leave small facets on curves. These methods suit thin, repairable finishes. Tool choice also supports intergenerational skill transfer. Children in Amish communities often learn to file a saw, sharpen a chisel, and set a plane. Holdfasts and bench dogs demonstrate fast, reliable workholding with safe body mechanics. Skills become repeatable practices rather than purchases. Because each tool imposes clear limits and gives immediate feedback, cause and effect remain visible in the finished piece.

Key Amish Woodworking Tools Still Used Today

The core kit stays compact and durable. It uses steel that sharpens easily and mechanisms built with simple parts, so maintenance stays straightforward. Speed depends on setup, sequence, and skill, not on a switch. The sections below show each tool’s readable cues and the practical reasons it still earns daily use.

Planes and Spokeshaves

Hand planes and spokeshaves define surface and line. A well-tuned smoothing plane takes thin shavings and leaves an even, low-gloss surface. Under raking light, you see the reflection move smoothly across the board instead of diffusing into a sanding haze. Faint, straight tracks along the grain show planing rather than abrasion. On edges and curves, spokeshaves cut small facets that appear under angled light.

Planes also handle more than finishing work. A jack or fore plane flattens boards. A jointer prepares long edges for accurate glue-ups. Spokeshaves refine chair spindles, round table edges, and eased rail corners. In quiet shops, these tools reduce dust and noise and provide immediate feedback.

Chisels, Drawknives, and Mallets

Bevel-edge chisels and mortise chisels form the base of hand joinery. Bevel-edge chisels pare to a line and clean tight corners. Mortise chisels lever chips from deep walls while holding straight. With sharp edges and consistent mallet strikes, these tools leave crisp corners and clean shoulders that indicate careful fitting. At joints, lines appear even and unfilled; in photos, scribe lines and baselines look clean, and edges appear cut rather than ground.

Drawknife takes off waste along the grain, especially on edges and chair parts that need a gentle round. When handled well, it leaves small facets you can see. Those facets point to hand shaping. A wooden mallet spreads force and protects chisel handles. Predictable strikes produce repeatable movement.

Braces, Hand Drills, and Hand Saws

A well-sharpened brace and auger cut clean, accurate holes. The tool finds its center with ease, moves at a steady pace, and clears chips as it goes. For smaller holes or lighter work, a hand drill or eggbeater drill does the job. When the entry shows a faint chamfer and the walls look straight and smooth, it often means the maker worked with care rather than haste or decoration.

Hand saws, including backsaws for joinery and panel saws for breakdown, leave lines that are straight with minor variation typical of hand sawing. The kerf produces fine saw flecks on end grain. On dovetails, rip-filed teeth cut to a line that ends just shy of the baseline, leaving a crisp arris for paring. Together with deliberate hole placement, these cues make the construction method evident.

Care and Sharpening

Ongoing care keeps quality repeatable. Shops make maintenance part of the workday. They wipe planes down, retract the irons, and wax the soles lightly. They store chisels with protected tips, organized by size. They hang saw teeth up to prevent dulling. These habits keep edges tidy and reduce the steps needed to finish the task.

Keep sharpening practical and repeatable. Work on a flat surface with a few grits. Follow the same order each time. Hollow-grind or add a gentle convex, then strop. Let the cut tell you if it’s right. The card scraper should lift steady shavings. The spokeshave should run without chatter. The mortise chisel should track straight. Touch up often and keep it brief. Stop between tasks to keep the tools cutting and to delay a full rehone.

Why Modern Woodworkers Still Choose Amish Tools

Modern woodworkers continue to gravitate toward Amish-made tools because of their exceptional reliability, durability, and precision. Unlike many mass-produced tools that prioritize speed and cost-cutting, Amish tools are crafted with a deep respect for traditional woodworking techniques. They are built with solid materials—often hardwoods and high-grade metals—and engineered to function smoothly without unnecessary mechanical complexity. This results in tools that feel balanced, sturdy, and intuitive in the hand. Woodworkers appreciate that Amish tools are designed to last for decades, often requiring only basic maintenance rather than constant replacement.

Another key reason for their popularity is the consistent performance and authenticity they offer. Amish tools tend to avoid heavy reliance on electricity, which not only aligns with traditional craftsmanship but also gives modern woodworkers more control and tactile connection to their work. Hand planes, chisels, mallets, and non-electric saws crafted by Amish makers provide a level of finesse that power tools sometimes can’t replicate. Many craftsmen say that these tools help them slow down, refine their technique, and produce cleaner, more intentional results.

Integrating Amish Tools into Modern Workshops

Integrating Amish tools into a modern workshop is easier than many assume, largely because these tools complement—rather than compete with—powered equipment. Woodworkers often use Amish hand tools for tasks that demand finesse, such as fine joinery, surface smoothing, edging, or final detailing. A high-quality Amish hand plane or chisel can achieve a level of precision and tactile control that power tools may struggle to match, especially on delicate woods or custom projects.

Another advantage of integrating Amish tools is the enhanced workflow and intentional craftsmanship they encourage. Many modern woodworkers use these tools as part of their finishing process to reduce machine marks, improve fit, and elevate the overall Amish furniture quality. Because Amish tools are built to last and require minimal maintenance, they naturally support a more sustainable, long-term workshop setup. For woodworkers who value precision, authenticity, and a deeper connection to their craft, Amish tools blend seamlessly into even the most high-tech workspace.

Bring the quiet standards of real handwork into your daily setup. The Grant Writer’s Desk keeps an honest, steady feel while letting you shift heights smoothly so your focus stays intact.

Conclusion

Traditional hand tool woodworking emphasizes durability and restraint. It relies on readable hand-tool surfaces, traditional joinery, and repairable wood finishes. In photos and listings, readers can spot these cues by checking surfaces under raking light, examining edges and corners, and reviewing close-ups of joinery and underside details. When these signs appear together, they make the construction method clear.

For a maker that reflects this approach, look to Lofty Furniture. Its focus on restrained design, honest materials, and durability helps you pick furniture that wears well with regular use.

Frequently Asked Questions (FAQs)

Why is Amish furniture so expensive?

Pricing reflects time, training, and materials. Quiet non-electric workshops trade speed for control, and that choice improves surfaces and joints. A hand plane cut creates a better base for finishing than bulk sanding. Hand-cut dovetails and mortise and tenon joinery demand skill, carry weight better, and repair cleanly.

Do the Amish use nails or screws?

Yes, when appropriate. Use fasteners to aid serviceability and wood movement, not to replace structural joinery. Attach a solid-wood top through elongated holes to allow seasonal expansion and contraction. Drive screws to hold the top while letting it move, which prevents splits. Mount hinges, locks, and runners with screws. Keep the intent clear: fasteners support the structure, not replace it.

Are Amish allowed to use power tools?

Practices vary by district. Many Old Order shops avoid electricity at the bench and rely on hand tools, foot power, and air tools driven by a central compressor located away from the bench. Some communities permit limited machine use for rough work such as ripping and initial surfacing, sometimes via line shafts or hydraulic power. Final fit and surface typically return to hand tools.