Buying furniture today isn’t just about choosing a style you like; it is about understanding what it’s made of and whether it’s built to last. And that starts with knowing the quality of the wood itself. While style and brand names capture your attention, it’s the lumber grades explained by the industry that truly determine longevity, durability, and a piece’s ability to withstand the test of time.

Key Takeaways:

- Lumber grading sorts wood by its clarity, strength, appearance, and overall usability.

- Higher grades like FAS for hardwoods and Select Structural for softwoods have fewer defects and are more usable for fine finishes.

- Understanding grade stamps and key grading factors allows modern furniture buyers to choose wood that matches both their budget and their expectations for style.

Let’s walk through what lumber grades really mean, how they’re determined, and how to use them to judge the true quality of the pieces you bring into your home.

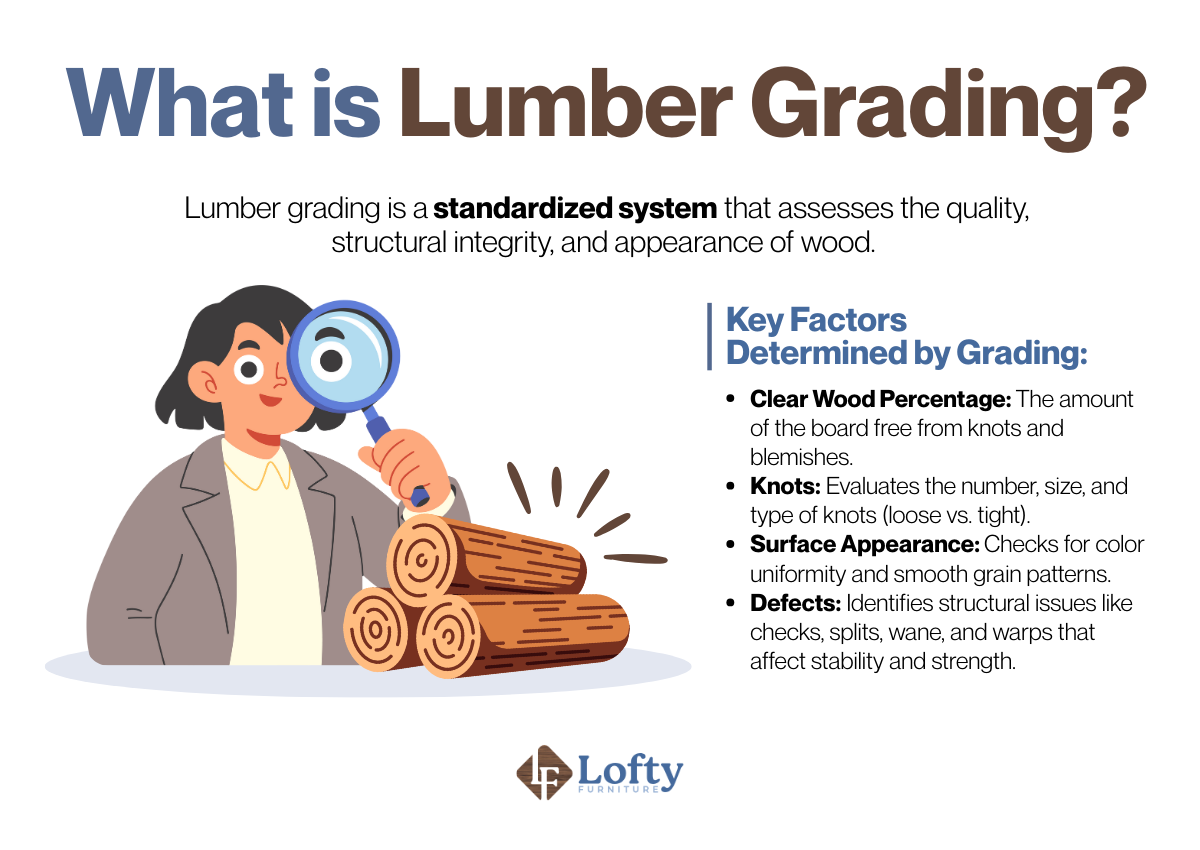

What is Lumber Grading and Why Does it Exist?

Lumber grading is a standardized system that evaluates the quality, appearance, and structural integrity of wood before it reaches manufacturers or consumers. It exists to make sure buyers know exactly what they’re getting, whether that’s premium, furniture-ready boards or more economical lumber with natural imperfections. Instead of relying on guesswork, the grading system sets clear expectations about strength, durability, and visual consistency. These grades also help ensure safety for load-bearing uses and fairness in pricing across the industry.

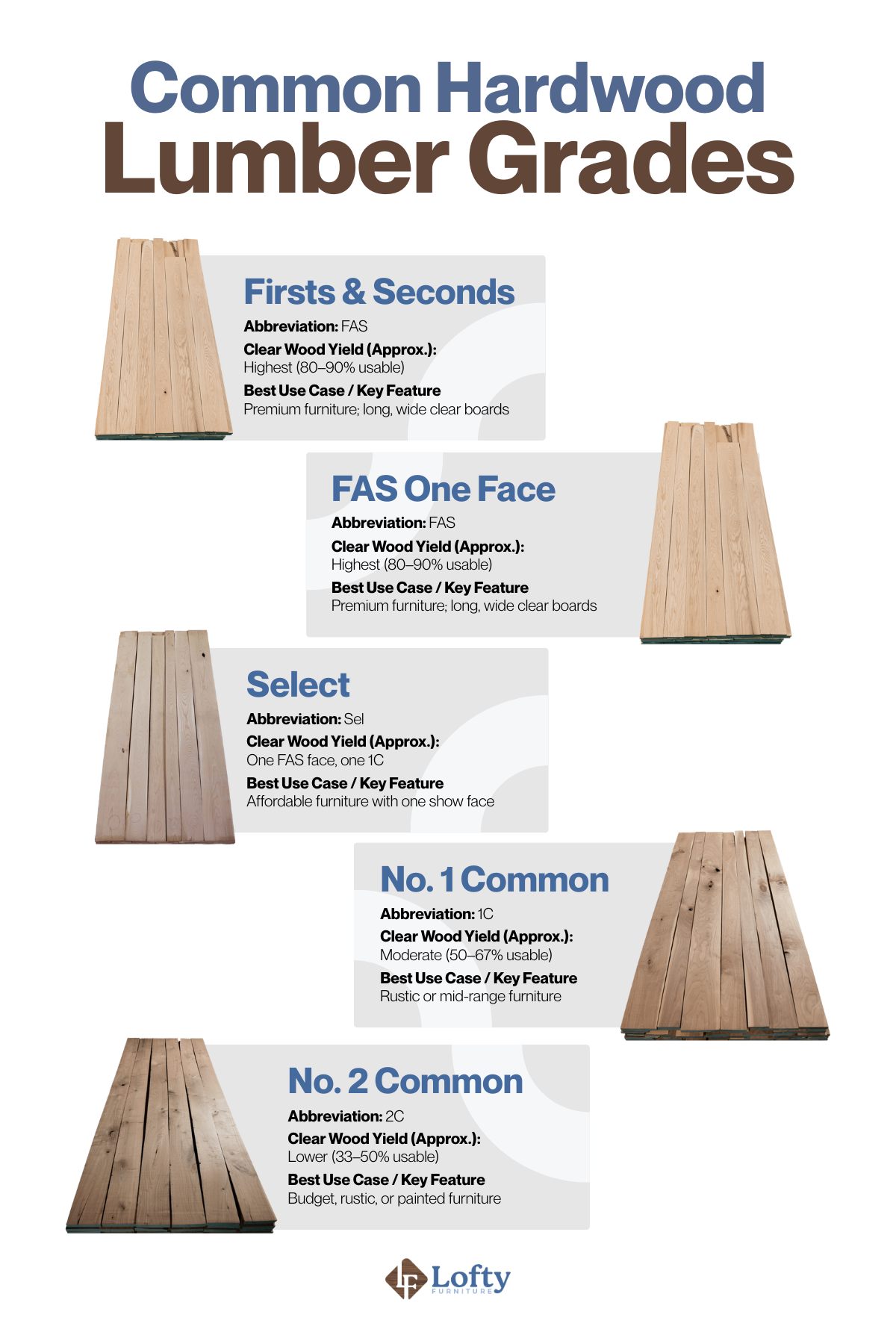

Hardwood Lumber Grades Explained

Hardwood grading in the U.S. follows the standards set by the National Hardwood Lumber Association (NHLA), a system created to bring consistency to a natural, highly variable material. These rules focus mainly on the amount of clear, usable wood each board contains, along with overall appearance and defect limitations. Below is a simple breakdown of the major grades you’ll see when shopping for furniture-quality hardwoods.

FAS (Firsts & Seconds)

FAS grade is the highest grade for hardwood lumber, offering the most clear and defect-free wood per board. It’s commonly used for fine furniture, cabinetry, and high-end architectural work where long, wide, clear pieces are required.

FAS One Face (F1F)

F1F means that one face of the board meets full FAS grade standards while the opposite face meets at least Select grade. This grade is ideal when only one side of the wood will be prominently displayed, such as drawer sides or parts of a frame.

Select (Sel)

Select grade is similar to F1F but in reverse: one face is FAS quality, and the other is at least No. 1 Common. This makes it a cost-effective choice for furniture where one visible face must look clean and consistent. It’s frequently used for tabletops, shelves, and decorative pieces.

No. 1 Common (1C)

No. 1 Common provides a good amount of usable wood but includes more knots, color variation, and shorter clear sections. It’s widely used for casual or rustic furniture where minor imperfections add character rather than detract from quality.

No. 2 Common (2C)

No. 2 Common includes boards with noticeable defects and smaller clear cuttings but still has enough usable wood for many value-oriented products. It’s popular for rustic, distressed, or painted furniture where flaws are either embraced or covered.

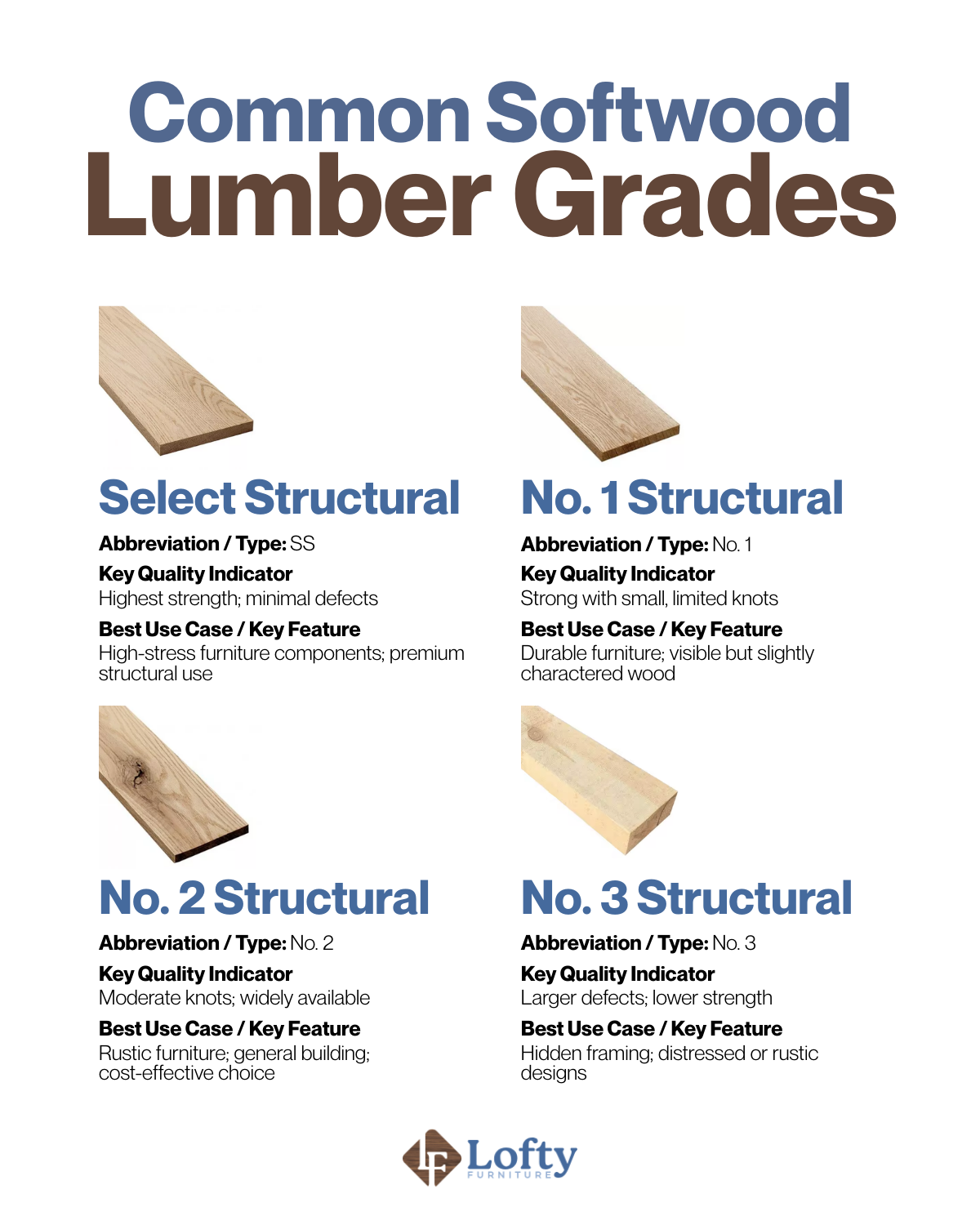

Softwood Lumber Grades Explained

Softwood grading follows two main paths: structural grading, which focuses on strength and load-bearing performance, and appearance grading, which evaluates visual quality for finish work. In the U.S., softwood grading is governed by the American Lumber Standard Committee (ALSC) through accredited agencies such as WWPA, SPIB, and WCLIB. Together, these systems help buyers choose the right type of softwood based on both performance and appearance.

Select Structural

Select Structural is the highest structural grade for softwoods, offering excellent strength and minimal natural defects. These boards have very small, tight knots and are straight, stable, and ideal for high-stress applications.

No. 1 Structural

No. 1 Structural lumber has strong load-bearing capability with slightly more knots and minor imperfections than Select Structural. The defects are still limited enough that the wood remains dependable for both structural and furniture uses.

No. 2 Structural

No. 2 is the most commonly sold structural grade due to its versatility and affordability. It contains more and larger knots, as well as moderate variations in grain and color. While it’s still structurally safe, it’s less predictable for high-stress applications..

No. 3 Structural

No. 3 Structural includes boards with more visible defects such as larger knots, checks, or minor warp. These imperfections reduce strength and make the lumber more suitable for non-critical or temporary uses.

Transform your home office with a solid wood Amish desk. Experience the lasting

Key Factors in Lumber Grading

Before a board earns its grade, inspectors look at several characteristics that affect both performance and appearance.

Clear Wood Percentage

Clear wood percentage refers to how much of the board is free from knots, blemishes, and natural irregularities. The higher the clear area, the more consistently smooth and workable the wood will be.

Number and Size of Knots

Knots are natural but they directly affect grades. Smaller, well-sized knots may simply add character, while large or loose knots weaken the board and make machining more difficult. Too many knots or the wrong kind can drop a board into a lower grade.

Surface Appearance and Color Uniformity

Even if a board is structurally sound, its surface appearance is crucial for furniture applications. Grading looks at consistency of color, minimal streaking, and smooth grain patterns. Uniformity ensures that pieces built from multiple boards look cohesive rather than mismatched.

Defects: Checks, Splits, Wane, Warps

Defects like checks (surface cracks), splits (through-cracks), wane (missing wood along edges), and warps (bends or twists) can significantly lower a lumber grade. These issues affect stability, strength, and how well the board can be milled or joined.

How to Choose the Right Lumber Grade for Your Furniture Needs

Choosing the right lumber grade isn’t about always picking the highest option; it’s about finding the best fit for your project, your style, and your budget. The key is to match the grade to the role the wood will play in your furniture piece.

1. Match Grade to Budget

Higher grades like FAS or Select look beautiful and offer plenty of clear, workable material, but they also come with a premium price. If you’re building a showpiece like a dining table, investing in higher grades can be worth it.

2. Match Grade to Furniture Type

Different furniture pieces place different demands on lumber. Tables and visible cabinet fronts benefit from higher appearance grades because the wood’s clarity and consistency will be front and center. Shelves and internal cabinet parts, however, can often use lower grades as long as the boards are structurally sound. Knowing which parts will be seen helps you choose efficiently.

3. Understand Overbuying vs. Underbuying

Overbuying happens when you pay for premium lumber where it won’t be noticed or needed, driving up project costs without real benefit. Underbuying, on the other hand, can lead to warping, breakage, or pieces that look lower quality than intended. The goal is to choose the grade that meets the functional and visual demands of the project—not more, not less.

Final Takeaway: Choosing Lumber with Confidence

Understanding lumber grades isn’t about memorizing technical rules; it’s about giving yourself the clarity to recognize real quality when you see it. Whether you’re buying ready-made furniture or sourcing lumber for your own builds, knowing how grades work helps you separate marketing fluff from meaningful craftsmanship.

With the basics of hardwood and softwood grades, defect classifications, and grade stamps under your belt, you can make informed decisions that match your style, budget, and expectations for durability. In the end, choosing the right lumber grade means choosing furniture that lasts longer, looks better, and brings more value into your home.

Frequently Asked Questions

Is #1 or #2 grade lumber better?

#1 grade lumber is generally better because it has fewer defects, tighter knots, and better structural reliability than #2. However, #2 is often perfectly suitable for rustic furniture or projects where small imperfections add character.

What is the best lumber grade?

For hardwoods, FAS is the highest grade, offering the most clear, defect-free material. For softwoods, Select Structural (SS) or Appearance Grade A is considered top-tier depending on whether you prioritize strength or looks.

What is the difference between Grade A and Grade B lumber?

Grade A appearance lumber has the cleanest surface with minimal knots and smooth, uniform color. Meanwhile, Grade B allows more visible knots and slight imperfections but still maintains good overall appearance. Grade A is preferred for premium or decorative pieces.

Are lower lumber grades still suitable for modern furniture styles?

Yes. Lower grades like No. 2 Common or No. 2 Structural are widely used in rustic, industrial, farmhouse, and distressed modern designs. These styles embrace imperfections such as knots and color variation, often turning them into intentional design features.

Does “clear grain” necessarily mean higher quality for every type of modern furniture?

Not always. Clear grain signals visual purity and ease of working, but some designs intentionally favor knots, color streaks, and texture for character. A perfectly clear board may look too plain for styles that rely on personality and organic patterns.